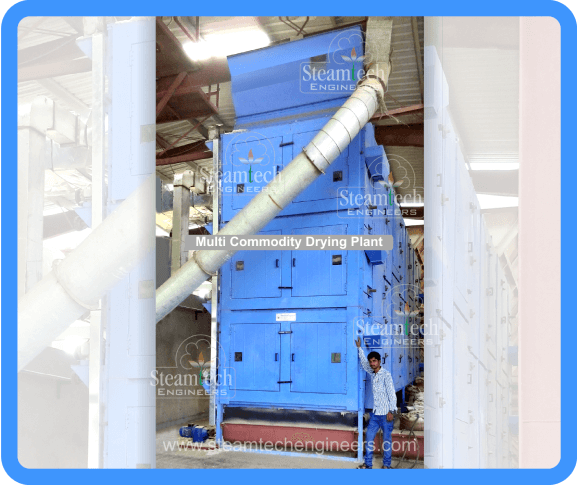

Steamtech Engineers is the established manufacturer of industrial multi commodity dryers. Our multi commodity dryer is a convective drying framework, which is helpful in various oil mills, warehousing, stock, grain processing plants, and other seeds/ grains related enterprises for drying. The multi commodity can be dried in a continuous cycle without denaturalizing its properties.

Steamtech can offer three types of dryers for the effect you need in the dried commodity.

- Belt Dryer

- Conical Dryer

- Vertical flow Dryer

Commodities you can dry in Steamtech multi commodity dryer:

| Very main | Main | Sub main | Sub |

|---|---|---|---|

| Dry fruit | Almonds Pistachio nuts Pecan nuts Macadamia nuts Hazelnut Chestnuts |

||

| Millet | Pumpkin seeds Quinoa Maize Corn Jowar or Sorghum Barley Oats Bulgur Buckwheat Bajra or Pearl Millet Rajgira or Amaranth Ragi or Finger Millet Kangni or Foxtail millet |

||

| Grains | Wheat Paddy Lupins Bird seeds |

||

| Legumes | Pulses | Beans | Faber beans Lima beans Mung beans Coffee Kidney beans Pinto benas Black beans Chick peas Navy beans Velvet bean Moth bean White beans French beans |

| lentils (dal) | Chana Dal Masoor Dal Urid Dal Tur Dal Moong Dal Toor Dal Fenugreek Chori dal |

||

| Peas | Pigeon peas Poona cow peas Black eyed peas Split peas |

||

| Oil seeds | Peanuts Soybean Sesame (til) Canola Cassava Chia Rapeseed Safflower Sunflower Neem seed Mahuva seed Hemp seed |

There are 4 types of energy source options available in the multi commodity dryer:

- Biomass coal fired

- GAS fired

- Diesel fired

- Electrical

The capacity of a multi commodity dryer varies from 20 tons to 500 tons per day.

The machine works with a convective drying system. The different type of commodities can be consistently feed into the dryer one by one directly from the warehouse/ stockroom or seed feeder in continuous manner with less efforts. The commodity is fed in the hopper of the Multi Commodity Dryer and gets spread for the uniform drying and is retained inside the dryer for specific time and further a valve is set at the exit point for controlled outcomes to achieve the ideal contact timing of the hot air blown and the seed/grains, henceforth giving the ideal moisture decline in a single step action in a continuous and uninterrupted mode. Likewise in this cycle the hot air is blown through the commodity to decrease the moisture the different agro commodities. Approach of drying chamber to ensure required overturning of the seeds so the overall surface of the agro commodity interacts with the hot air blown, to obtain the best outcome.

- The dryer doesn’t give a traditional platform drying facility consequently it saves your space and time.

- Helps you with drying seeds/ grains/ pulses/ millet even in the wet environment when natural sun drying is not available.

- It fundamentally benefits the oil plant and multi commodity processing organizations as they can dry their agro commodity in the early season and blustery season as well.

- They give you better quality as compared to over-wet seed/ grains smashing.

- It ensures you to inflate your production compared to over moist agro commodity.

- Also allows you to have smooth management of the processing plants.

- They are designed to have required moisture for the multi commodity plant.

- Dryers are worked with a fully automatic system.

- They have the continuous activity of agro commodity.

- They are suitable for oil industries and multi commodity units.

- Can work in low power demand as well.

- Dryer machine has an auto temperature controlling system.

- Makes it possible to have accurate drying of the entire multi commodity.

- Online processing of multi commodity is possible.

- It completes the process with gentle drying; the product is not broken down.

- One time investment for the best quality.

- MODULAR CONSTRUCTION: The sectional construction saves time in project planning, assembling, transportation and lastly establishment.

- ENERGY EFFICIENCY: Air flow can be overseen individually according to the prerequisite to ensure ideal heat transfer is given to the material while controlling exhaust air temperature, subsequently prompting energy proficiency.

- PROCESS ADAPTATION: Every parameter like, Temperature, Retention period of multi commodity can be independently controlled to fulfill drying requirements.

- MAKE IN INDIA: The machine is 100 percent primitive and patented. We offer quality assistance and all parts are readily accessible in stock. We are the companion you can rely on.

Get In Touch