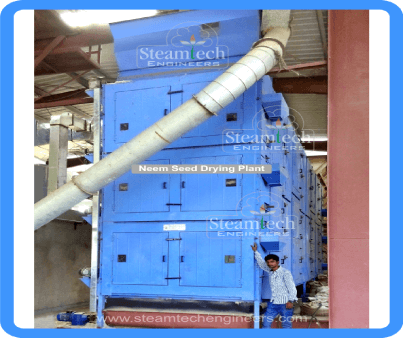

Neem seed Dryers are generally installed by oil plants for crushing of these seeds with medicinal worth. Neem seed oil has immense importance in Ayurveda and its cake is frequently utilized as manure.

There are 4 types of energy source options available in the Neem Seed dryer:

- Biomass coal fired

- GAS fired

- Diesel fired

- Electrical

The capacity of the dryer varies from 20 ton to 300 tons per day.

The Neem Seed dryer machine works as a convective drying system. The Neem Seeds are dried and cleaned by giving a continuous flow of hot air, at a particular speed and a maintenance time by passing it over a thin air permeable belt through hot air distribution slits. The temperature, feeder and retention time can be controlled utilizing an electrical control panel board. The activity is constant and the drying is done effectively by passing the air through the bed thickness.

- Very useful to run industry as procurement season is short.

- Manual Platform Drying isn’t needed consequently manpower and time is saved.

- Warehousing, Oil factories and Fertilizer producing Industries can work in early season period and stormy season period too.

- Oil recovery and production can be expanded when contrasted with over-moist Neem seed expelling.

- Better quality and color of cake is maintained.

- Online crushing in oil factories from handling plants is attainable, subsequently work for bagging, stacking, and re-feeding is saved.

- Smooth administration of oil plants. A suitable moisture level for the warehousing storage can be kept up.

- Continuous activity.

- Ensures Auto temperature controlling framework.

- Appropriate for online crushing from cleaning facilities.

- Uniform drying.

- Gentle drying of Neem seeds so that quality isn’t weakened.

- Profoundly energy proficient.

- Enhances Low power demand.

- Closed vessel activity considering safety.

- Completely automatic operation.

- MODULAR CONSTRUCTION: The sectional development diminishes time in project planning, assembling, transportation and lastly establishment.

- ENERGY EFFICIENCY: Air stream can be conducted individually according to the prerequisite to ensure ideal heat transfer is given to the material while controlling exhaust air temperature, subsequently prompting to energy proficiency.

- PROCESS ADAPTATION: Every variable for example, Air stream, Temperature, Retention period of cottonseed can be independently controlled precisely to suit your drying prerequisite.

- MAKE IN INDIA: The machine is 100 percent primitive and patented. We offer quality assistance and all parts are readily accessible in stock. We are the partner, you can depend on.

Get In Touch