Kapas Feeder

Click here

Kapas Belt (Seed Cotton Inclined Belt Conveyor)

Click here

Seed Cotton Feeding Trolley

Click here

Cotton Lint Pneumatic System

Click here

Cotton Lint Humidification

Click here

Semi Automatic Feeding System

Click here

Cotton Lint Cleaner

Click here

Lint Belt

Click here

Moisture Analyzer

Click here

Bale packing System

Click hereKapas Feeder

Now a days many of the Cotton Ginning factories are using loaders for kapas feeding in to the feeding belt hopper to supply Kapas into the kapas feeder system for opening each cotton ball of seed cotton and uniformly feeding for further processing with cleaning and magnetic plate. The seed cotton belt conveyor is built according to internationally accepted standards and is a go-to for all cotton ginning companies. We also provide customizations according to client specifications and requirements.

The machine has storage capacity as per ginner’s requirement.

In order to overcome the manual feeding method, Steamtech Engineers introduces a fully automatic system. In this method, loader dumps the seed cotton (kapas) in this machine which is placed near the feeding hopper.

- Continuous & controlled feeding.

- Improves Production due to uniform Kapas feeding to the kapas conveying system.

- Patti & Dust is partially cleaned.

- Problems of Manual feeding is eliminated.

- Labour cost for kapas feeding is drastically reduced.

- Manpower is saved.

- Can be easily feed with Loader.

- It Pre-cleans the seeds cotton.

- Bearings of support rollers are placed inside the rollers for longer life.

- It is highly efficient and reduces time and energy consumption providing faster production rate.

Kapas Belt (Seed Cotton Inclined Belt Conveyor)

Seed cotton conveying belt (Kapas Belt) is a uniquely designed rubber conveyor belt by Steamtech Engineers for easing down the conveying process. Seed cotton is conveyed from storage to ginning plant efficiently.

Upto 200 tons per day.

Kapas belt system has a Driving system which rotates rubber coated head pulley which in turn rotates the specially designed rubber conveyor belt. The seed cotton (kapas) is conveyed on this inclined belt and fed into the ginning plant.

- Hassle free conveying of seed cotton.

- Fully automatic system.

- Less power consumption.

- Long life of rubber conveyor belt hence minimum maintenance cost.

- Sturdy and rigid body.

- Self-cleansing system is inbuilt which facilitates proper alignment of the belt.

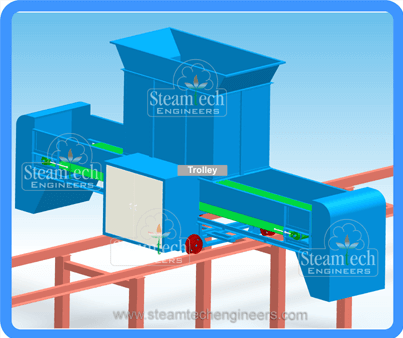

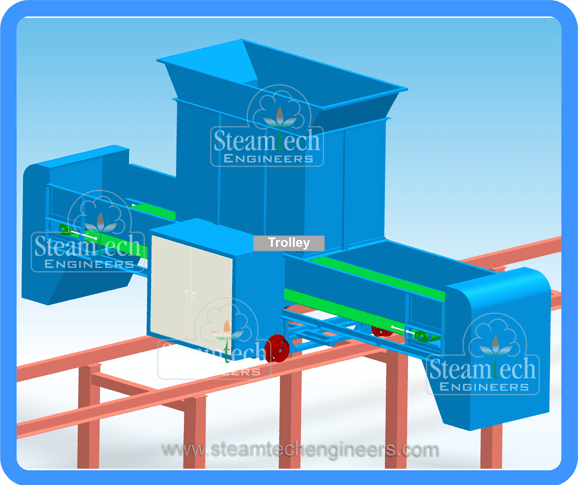

Seed Cotton Feeding Trolley

New Generation Trolley system is one of the finest and most advanced technologies developed by Steamtech Engineers in the country for Cotton Ginning Industry. Trolley hopper stores bulk quantity and feeds to gin stands as per its requirements. Uniform feeding of seed cotton at proper time intervals increases productivity.

200Kgs- 300Kgs per Cycle.

Trolley Runs above gin stand and checks the quantity of seed cotton filled inside the Auto feeder of Gin stand with special sensors. If Auto-Feeder is empty, it refills and incase it is full, it passes by. It also detects and feeds the partially filled Auto-Feeder. Incase the trolley hopper becomes empty it retracts itself to the home position for refilling itself making the whole process fully automatic and flawless.

- It always keeps all the Auto-Feeders of the Gin stand fully filled resulting into higher productivity.

- Higher productivity can be achieved due to uniform feeding in the system.

- Uniquely designed hopper and feeders allow seed cotton to flow through easily without any blockage.

- A PLC (Programmable Logic Controller) panel is provided to facilitate variations in feeding rate and cycle rate.

- The Trolley is sturdy and robust hence has low maintenance cost.

- It consumes low amount of electricity.

- It not only caters empty or full Auto-Feeders but also Partially filled ones through powerful sensors.

- The machine is designed to work 24 x 7 for the best output.

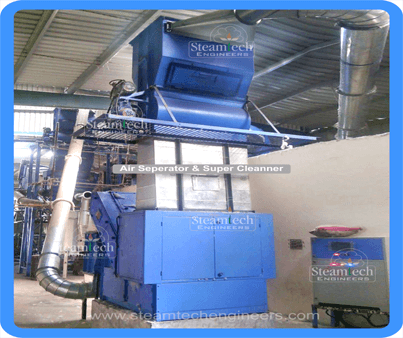

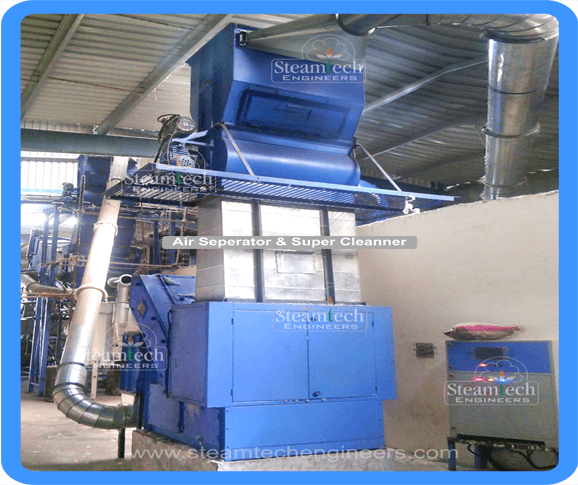

Cotton Lint Pneumatic System

The lint pneumatic suction system is one of its kind and made of various components like ducts, air separator, blower and cyclone separator. It is manufactured by steamtech engineers under highly controlled conditions to provide standard results. It is one of the modern methods devised to transport or convey cotton lint along with getting rid of shorter cotton fibers, dust and other contamination.

24-70 ton per day.

Cotton lint is conveyed with suction of air into the air separator where the cotton is separated from impurities and air and an air lock enables cotton lint to come out of the air separator.

- This system is very useful where elevation difference is huge and conveyor belts form very steep slopes.

- Cotton lint is conveyed with retaining its original form and shape.

- The duct can convey lint even in a free form path (any curves) and not just straight one.

- Make in India: The machine is 100% indigenous and patented. We provide quality service and all parts are readily available in stock. We are the partner, you can rely on.

Cotton Lint Humidification

Cotton lint humidification and moisture restoration system is a patented product of steamtech engineers and it restores cotton moisture automatically which is reduced during the ginning process. After formation of cotton lint bales, moisture retention system retains moisture content in bales which are stored in godowns.

12-36 bales/ hour.

The operating principle of Cotton lint humidification system is, Vapor is generated and cotton is humidified up to desired extent automatically in controlled environment irrespective of external weather.

- Strength of cotton fiber is improved.

- Even humidification can be achieved in whole cotton bale.

- Colour of cotton fiber is improved.

- Humidification can be done in accordance to international standards.

- It prevents formation of fungus in the cotton bales when stored for longer duration.

- PLC provides controlled humidification of specified percentage round the clock unless changed.

- It has sturdy and robust body

- Modular Construction : The sectional construction reduces the time in project planning, manufacturing, transportation, and finally installation.

- Energy efficiency: Vapour flow can be managed individually as per the requirement to make sure optimum humidification.

- Process adaptation: Each parameter such as Vapour flow, Temperature, Retention time of product can be individually managed exactly to suit your humidification requirement.

- Make in India: The machine is 100% indigenous and patented. We provide quality service and all parts are readily available in stock. We are the partner, you can rely on.

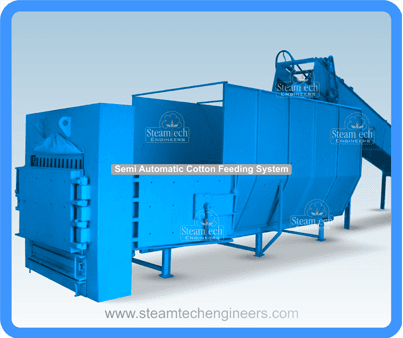

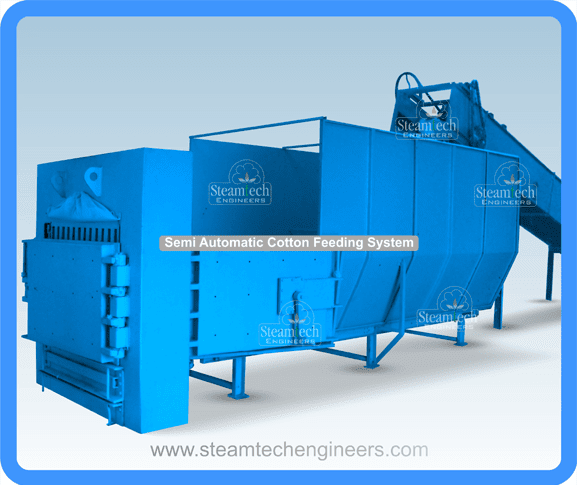

Semi Automatic Feeding System

Semi automatic feeding system is an intermittent storage system which can be fitted along with manual baling press. A continuous supply of cotton lint can’t be handled in manual baling press and hence the semi automatic feeding system stores excess cotton lint and supplies as and when required to the manual baling press.

Upto Lint of 1 cotton bale can be stored.

Continuously incoming cotton lint is stored and on pushing a button, it can be fed into the manual baling press.

- Contamination of ginned cotton is avoided as its continuous supply can be stored inside the feeding system.

- Easy handling of the cotton lint.

- Less workers can manage the process.

- Low consumption of electricity.

- The process becomes hassle free and semi-automatic instead of manual.

- Sturdy and seasoned body of the machinery pertaining to low maintenance cost.

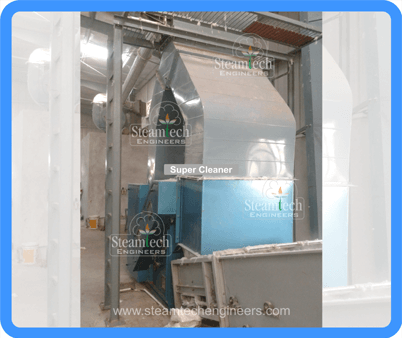

Cotton Lint Cleaner

Inclined Lint Cleaner is one of the accessory equipment developed by Steamtech Engineers responsible for the cleaning of cotton lint. Seed coats, short fibers, leafy matter, micro-dust are separated from ginned lint. The Lint Cleaner improves lint grade and appearance with the reduction in trash content & other contamination.

1200/1500/ 2000 Kg/Hour

No. of cleaning cylinders – 3 and 6 cylinders

Cotton Lint is controlled fed inside lint cleaner and Specially designed grid bars and rollers having forged beaters work on the lint to clean it.

- Remove seed coats from ginned lint.

- Low electricity consumption.

- Opens lint for excellent humidification.

- Lint Bypass Arrangement is provided in our system.

- Different models with different feeding systems.

- Robust construction.

- Easy maintenance.

- Dynamically balanced rollers for smooth and vibration free operation.

Lint Belt

Cotton lint is supplied to the automatic revolving baling press on lint belt. The width of the belt is in accordance to the width of baling press.

24-70 ton per day.

Lint belt has a Driving system which rotates rubber coated head pulley which in turn rotates the specially designed rubber conveyor belt. The cotton lint is conveyed on this inclined belt and fed into the baling press.

- Easy conveying system as compared to the conventional manual methods.

- It works as a time saver.

- It increases productivity.

- The lint belt facilitates uniform bale formation.

- Conveys lint without and loses.

- Low power consumption.

Moisture Analyzer

A device providing advancement of sense of touch and feel, an accurate, compact, hand held instrument for direct measurement of moisture in cotton bale and also in yarn is called a moisture analyzer. It is an analog version.

3.5 – 20 % moisture.

Cotton moisture meters work using electrodes to pass an electrical current through the cotton and measuring the resistance to the current. The less moisture there is in the cotton, the more resistance there will be to the electrical current. The more moisture there is in the cotton, the less resistance there will be to the electrical current.

- Accurate readings.

- Easy handling.

- Long working life.

- Handy and easily portable.

- Make in India: The machine is 100% indigenous. We provide quality service and all parts are readily available in stock. We are the partner, you can rely on.

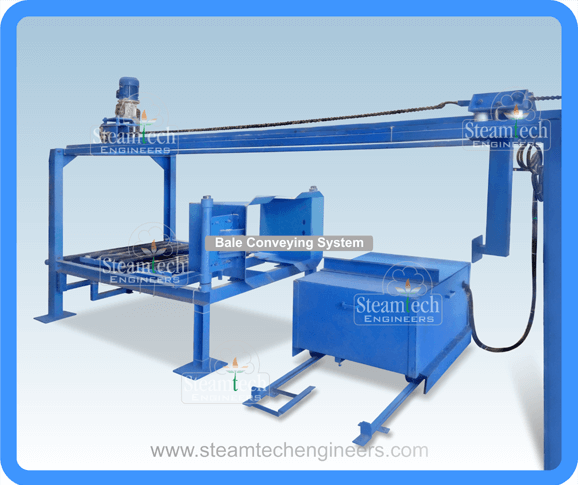

Bale packing System

Bale packing system is designed specially for weighing and packing bales. As cotton bales are heavy, to provide hassle-free handling, our machine also bags them up. The whole process is automatic, fast, caters easy handling and requires minimum supervision even by unskilled labour.

12-40 bales per hour.

After bales is packed from press, the automatic system collects bale from the press and transfers it to weighing scale. Post weighing, bale is packed inside the bag and is moved towards the exit.

- The machine empowers one to weigh the heavy bales without having to lift it manually.

- It also provides the facility to packaging bales inside bags for further transportation.

- Even unskilled labour can operate it easily.

- PLC panel is inbuilt for providing regulations in cycles.

- Make in India: The machine is 100% indigenous. We provide quality service and all parts are readily available in stock. We are the partner, you can rely on.

Get In Touch